MCH 22/MCH 30/ MCH 36/MCH 45 BLOCK |

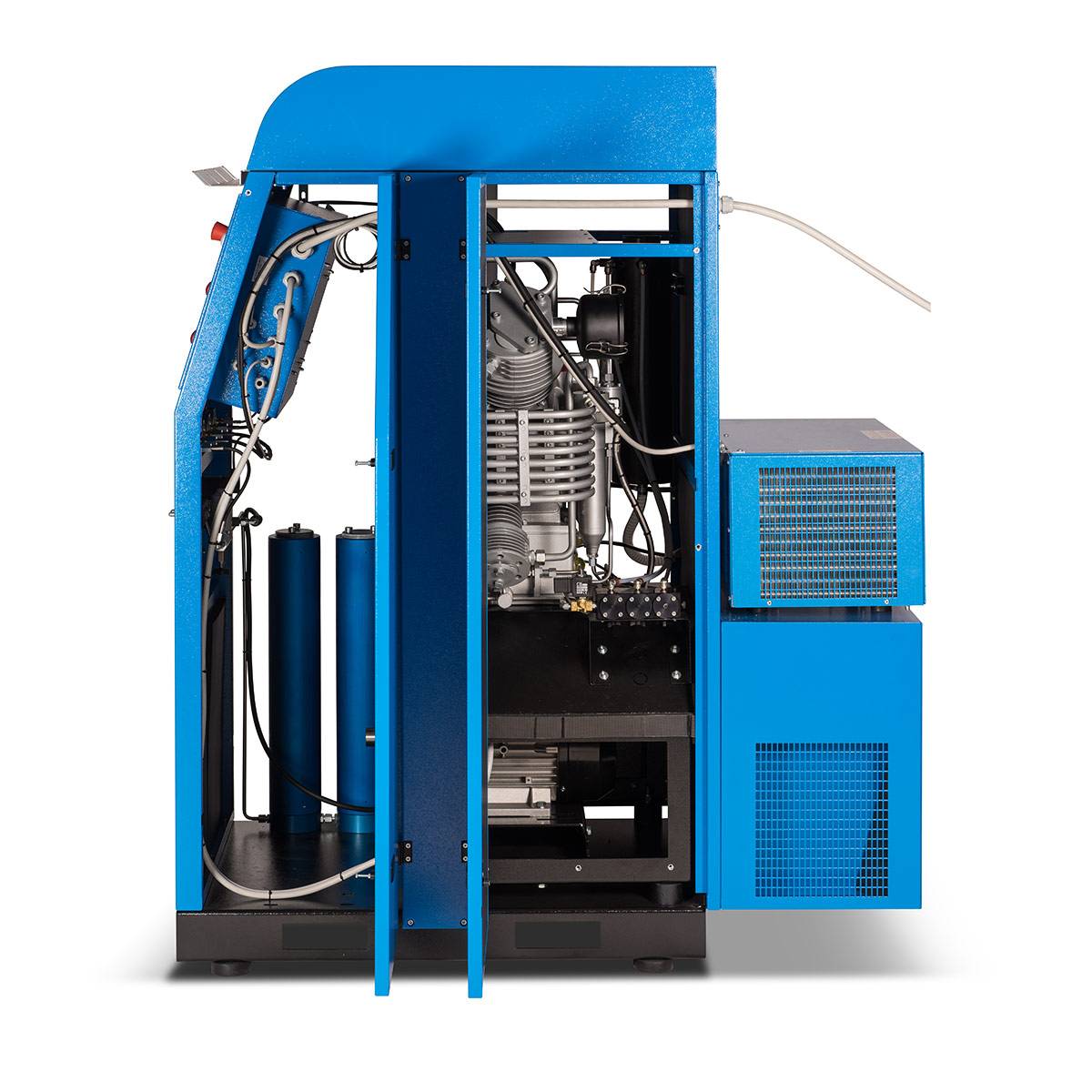

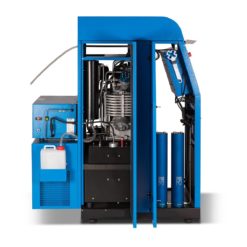

The SILENT model represents excellence in soundproofing. It has been designed to meet the needs of very intensive uses and when large filling capacities are required. Equipped with 4 front filling connections for high pressure hoses (from 232 to 420 bar), a control panel and an electrical display. They are equipped with a three-phase electric motor and powerful pumping units (MCH 22, MCH 30, MCH 36 and MCH 45 depending on the specific model). The structure, which has been specially designed to improve soundproofing, is used to go below the threshold of 70 dB in operation. For the longer life of the filters, the external dryers RF 500 and RF 1000 are available. Optionals include: electronic touch screen panel, Presec for filter saturation control and remote filling panel.

Technical drawing

COLTRI MCH 22 SILENT

Drive: Three-phase Electric Motor

Pumping group capacity: 450 l/m – 27,00 m³/h – 15.89 CFM FAD

Filling time: 4 min. 30 sec.

* Cylinder filling time from 10 l-0/200 bar (cylinder filling measurement from 0 to 200 bar ± 5%)

Operating pressure: 232 – 330 – 420 bar or 3365 – 4786 – 6092 PSIG

Net weight: 445 kg – 981 Lbs

Noise level: 70 db

COLTRI MCH 30 SILENT

Drive: Three-phase Electric Motor

Pumping group capacity: 550 l/m – 33,00 m³/h – 19.42 CFM FAD

Filling time: 4 min.

* Cylinder filling time from 10 l-0/200 bar (cylinder filling measurement from 0 to 200 bar ± 5%)

Operating pressure: 232 – 330 – 420 bar or 3365 – 4786 – 6092 PSIG

Net weight: 445 kg – 981 Lbs

Noise level: 70 db

COLTRI MCH 36 SILENT

Drive: Three-phase Electric Motor

Pumping group capacity: 650 l/m – 39,00 m³/h – 22.95 CFM FAD

Filling time: 3 min.

* Cylinder filling time from 10 l-0/200 bar (cylinder filling measurement from 0 to 200 bar ± 5%)

Operating pressure: 232 – 330 – 420 bar or 3365 – 4786 – 6092 PSIG

Net weight: 445 kg – 981 Lbs

Noise level: 70 db

COLTRI MCH 45 SILENT

Drive: Three-phase Electric Motor

Pumping group capacity: 750 l/m – 45,00 m³/h – 26.49 CFM FAD

Filling time: 2 min. 40 sec.

* Cylinder filling time from 10 l-0/200 bar (cylinder filling measurement from 0 to 200 bar ± 5%)

Operating pressure: 232 – 330 – 420 bar or 3365 – 4786 – 6092 PSIG

Net weight: 455 kg – 1003 Lbs

Noise level: 70 db

|

Components 1. Frame 2. Control panel 3. On pushbutton 4. Off pushbutton 5. Condensate drain pushbutton 6. Power indicator light 7. Wrong rotation direction alert 8. Oil level warning light 9. Operating hours counter 10. Cabinet interior / cooling air temperature 11. Emergency pushbutton 12. Automatic shutdown pressure switch 13. Oil pressure gauge 14. 1st stage pressure gauge 15. 2nd stage pressure gauge 16. 3rd stage pressure gauge 17. Fourth stage pressure gauge 18. Refill hoses connection 19. Oil level gauge 20. Oil drain valve 21. Purifier filter 22. Condensate collection container 23. Condensate collection tank 24. Engine 25. Compressor 26. Air filter 27. Final condensate separator 28. 1st stage 29. 2nd stage 30. 3rd Stage 31. Fourth stage 32. Crankcase 33. Oil filler plug 34. Safety valve 35. Maintenance valve 36. Cooling fan 37. Belt 38. Anti-vibration devices 39. Refill tubes 40. Refill valve 41. Condensate separator |

|

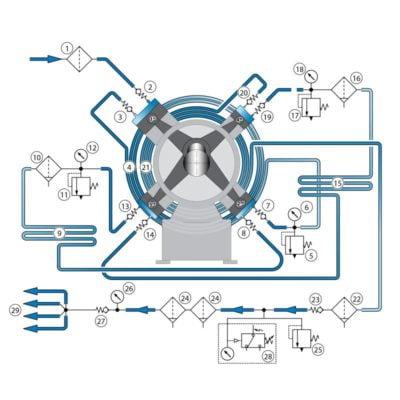

Components 1. Aspiration filter 2. Intake valve 1st stage 3. Discharge valve 1st stage 4. Cooling pipe 1st-2nd stage 5. Safety valve – 1st stage 6. Pressure gauge 1st stage 7. Intake valve 2nd stage 8. Discharge valve 2nd stage 9. Cooling pipe 2nd-3rd stage 10. Condensate separator 11. Safety valve – 2nd stage 12. Pressure gauge 2nd stage 13. Intake valve 3rd stage 14. Discharge valve 3rd stage 15. Cooling pipe 3rd-4th stage 16. Condensate separator 17. Safety valve – 3rd stage 18. Pressure gauge 3rd stage 19. Intake valve 4th stage 20. Discharge valve 4th stage 21. Final cooling pipe 22. Condensate separator 23. Non return valve 24. Active carbon molecular screen filter 25. Safety valve 26. Pressure gauge 4th stage 27. Pressure maintaining valve 28. Pressure switch 29. Flex hoses |

|

Components 1. Aspiration filter 2. Intake valve 1st stage 3. Discharge valve 1st stage 4. Cooling pipe 1st-2nd stage 5. Safety valve – 1st stage 6. Pressure gauge 1st stage 7. Cooling pipe 1st-2nd stage 8. Intake valve 2nd stage 9. Discharge valve 2nd stage 10. Cooling pipe 2nd-3rd stage 11. Condensate separator 12. Safety valve – 2nd stage 13. Pressure gauge 2nd stage 14. Intake valve 3rd stage 15. Discharge valve 3rd stage 16. Cooling pipe 3rd-4th stage 17. Condensate separator 18. Safety valve – 3rd stage 19. Pressure gauge 3rd stage 20. Intake valve 4th stage 21. Discharge valve 4th stage 22. Final cooling pipe 23. Condensate separator 24. Non return valve 25. Active carbon molecular screen filter 26. Safety valve 27. Pressure gauge 4th stage 28. Pressure maintaining valve 29. Pressure switch 30. Flex hoses |

STANDARD EQUIPMENT: |

|

OPTIONAL EQUIPMENT: |

| Weight | 90000 g |

|---|

Related products

Filling Stations

COLTRI COMPRESSOR MCH 13/ MCH 16/ MCH 21/ MCH 23 SUPER SILENT TPS

Filling Stations

FILL CONTAIMENT CABINET

Filling Stations

Filling Stations

COLTRI COMPRESSOR MCH 13 / MCH 16 / MCH 18 / MCH 16 EM ERGO ET

Filling Stations

Filling Stations